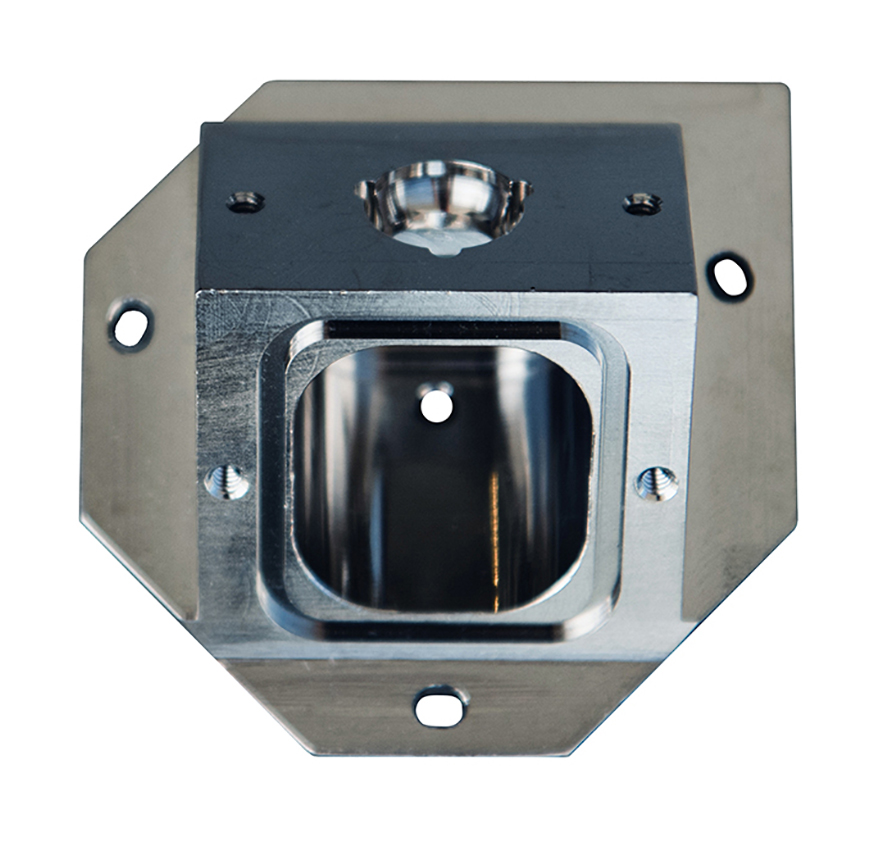

RF Power Electronic Enclosure

RF Power Electronic Enclosure

This part was a prototype power supply unit, machined for a startup, making power supply units for the US Government. Unique properties of these parts are machining on all sides, multiple processing requirements and tight project time-lines. The part started as a billet 6061-T651 Plate, and partially machined. Concluding the first machining process, the part was Black Anodize per Mil-A-8625, Type II, Class 2. The final machine process was to machine the interior of the part to the finish dimensions, which also included several tapped holes. Concluding the final machining process, the part was Gold Chemical Filmed. The last process was laser engraving the part marking requirements. The benefit to our customer was a fast turn-around, correctly machined to meet their exacting requirements and within budget.

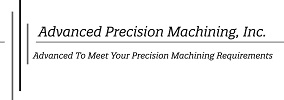

Gas Optic Housing

This project was designed and machined for a medical device manufacturer. The main function of this part was an optic holder for the laser to calibrate gas during the surgery process. The unique challenges of this part were many compound surfaces that had critical requirements for the end performance. Other factors were the finishing requirements, which was electroless Nickel plated. We were successful delivering this part due to the skill set of the employees at APM, the resources to inspect and validate the final requirements and in our communication to customers during critical processes to achieve the final results.

Wafer Inspection Plate

This plate is a vacuum chuck for a cleanroom wafer inspection test. The material is A2 Tool Steel, machined to near net size then ground to the finish dimension. The most critical dimension was a .070+/-.0001 Step. Working with both staff and outside suppliers, we were able to develop a process that produced high yields and consistent results and were able to cut our lead-time in half (from eight weeks to four weeks for small lot quantities). The processing required a copper flash, followed by Electroless Nickle and concluded with the Gold Plating.

Mirror Optic Flexure

This device was designed to be used to adjust mirror optics. The machining processes included machining all sides and using a wire EDM to cut the flexure slots. The parts were bead blasted prior to anodize to provide a light absorbent surface. Upon completion, the part was laser part marked per customer requirement.